Liming Group's green mining production line can process 1,000 tons of materials per hour, producing fine crushed stone aggregates and machine-made sand to meet high-standard engineering needs, while reducing operating costs, and achieving both econ

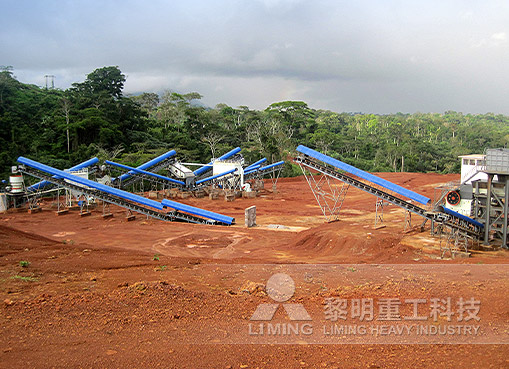

Liming Group's green mining production line can process 1,000 tons of materials per hour, producing fine crushed stone aggregates and machine-made sand to meet high-standard engineering needs, while reducing operating costs, and achieving both economic and environmental benefits.

Under the current background of rapid development of infrastructure, the demand for high-quality sand and gravel aggregates continues to grow. The green mining production line solution provided by Liming Group not only meets market demand, but also provides new ideas for efficient resource utilization.

Click to consult to learn about the construction plan of the sand and gravel production line

Technical characteristics and process highlights

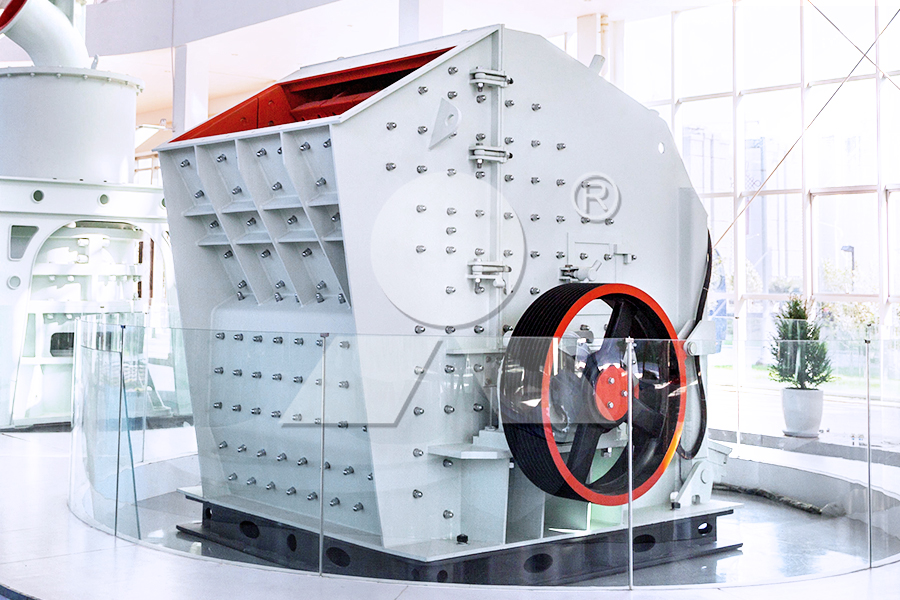

This production line adopts advanced wet process technology and is specially designed for the characteristics of limestone raw materials. It is mainly equipped with three core equipment: HST series single-cylinder hydraulic cone crusher, VSI5X series sand making machine and S5X heavy-duty vibrating screen, forming a complete production system. It can process 1,000 tons of materials per hour and produce fine crushed stone aggregates and machine-made sand that meet engineering standards.

The production line has many significant advantages:

The advanced sand making system adopts VSI5X vertical shaft impact crushing technology to ensure that the finished product has a rounded shape and reasonable gradation, which fully meets the needs of high-standard engineering projects such as highways and commercial mixing stations. The unique sand and gravel co-export process design can flexibly adjust the production mode according to the real-time market demand, greatly improving the adaptability of the production line.

In terms of wear-resistant material application, the production line adopts a full thin oil lubrication system and selects high-quality wear-resistant parts. Actual operation data shows that this configuration effectively extends the service life of the equipment and reduces the maintenance frequency compared with similar products, thereby significantly reducing operating costs. The flexible transmission system configured with the S5X heavy-duty circular vibrating screen can effectively avoid equipment damage caused by sudden power outages, providing a guarantee for continuous and stable production.

Application prospects

The successful operation of the production line provides a stable supply of raw materials for regional infrastructure construction. Its flexible process configuration can be quickly adjusted according to changes in market demand, with good economic and environmental benefits. The finished product particle shape control technology is particularly suitable for projects with high requirements for aggregate quality.

Previous: SMP Crusher

Next: SMP Crusher

Liming Group's green mining production line can process 1,000 tons of materials per hour, producing fine crushed stone aggregates and machine-made sand to meet high-standard engineering needs, while reducing operating costs, and achieving both econ

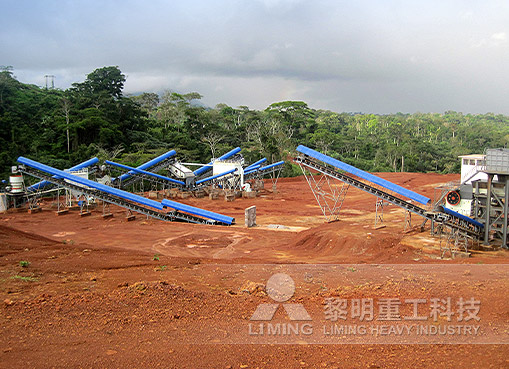

Liming Group's green mining production line can process 1,000 tons of materials per hour, producing fine crushed stone aggregates and machine-made sand to meet high-standard engineering needs, while reducing operating costs, and achieving both economic and environmental benefits.

Under the current background of rapid development of infrastructure, the demand for high-quality sand and gravel aggregates continues to grow. The green mining production line solution provided by Liming Group not only meets market demand, but also provides new ideas for efficient resource utilization.

Click to consult to learn about the construction plan of the sand and gravel production line

Technical characteristics and process highlights

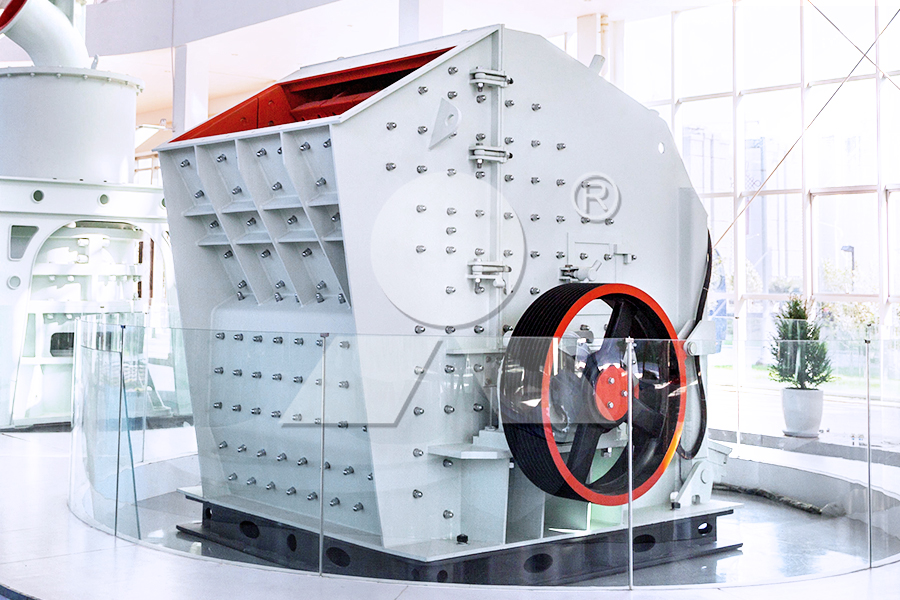

This production line adopts advanced wet process technology and is specially designed for the characteristics of limestone raw materials. It is mainly equipped with three core equipment: HST series single-cylinder hydraulic cone crusher, VSI5X series sand making machine and S5X heavy-duty vibrating screen, forming a complete production system. It can process 1,000 tons of materials per hour and produce fine crushed stone aggregates and machine-made sand that meet engineering standards.

The production line has many significant advantages:

The advanced sand making system adopts VSI5X vertical shaft impact crushing technology to ensure that the finished product has a rounded shape and reasonable gradation, which fully meets the needs of high-standard engineering projects such as highways and commercial mixing stations. The unique sand and gravel co-export process design can flexibly adjust the production mode according to the real-time market demand, greatly improving the adaptability of the production line.

In terms of wear-resistant material application, the production line adopts a full thin oil lubrication system and selects high-quality wear-resistant parts. Actual operation data shows that this configuration effectively extends the service life of the equipment and reduces the maintenance frequency compared with similar products, thereby significantly reducing operating costs. The flexible transmission system configured with the S5X heavy-duty circular vibrating screen can effectively avoid equipment damage caused by sudden power outages, providing a guarantee for continuous and stable production.

Application prospects

The successful operation of the production line provides a stable supply of raw materials for regional infrastructure construction. Its flexible process configuration can be quickly adjusted according to changes in market demand, with good economic and environmental benefits. The finished product particle shape control technology is particularly suitable for projects with high requirements for aggregate quality.

Previous: SMP Crusher

Next: SMP Crusher

Which brand of crusher is good? How to choose the manufacturer

Which brand of crusher is good? How to choose the manufacturer How to configure a 400 tons per hour sand and gravel production line

How to configure a 400 tons per hour sand and gravel production line How to choose equipment for a 500 ton/hour granite production line

How to choose equipment for a 500 ton/hour granite production line How to crush aluminum ore and what equipment is needed

How to crush aluminum ore and what equipment is needed Professional crusher manufacturers analyze the advantages of dry sand making technology

Professional crusher manufacturers analyze the advantages of dry sand making technology Which brand of crusher is good? How to choose the manufacturer

Which brand of crusher is good? How to choose the manufacturer How to configure a 400 tons per hour sand and gravel production line

How to configure a 400 tons per hour sand and gravel production line How to choose equipment for a 500 ton/hour granite production line

How to choose equipment for a 500 ton/hour granite production line How to crush aluminum ore and what equipment is needed

How to crush aluminum ore and what equipment is needed Professional crusher manufacturers analyze the advantages of dry sand making technology

Professional crusher manufacturers analyze the advantages of dry sand making technology